Automated Production Line

(Click on the image below to watch the video)

|

|

|

|

|||||

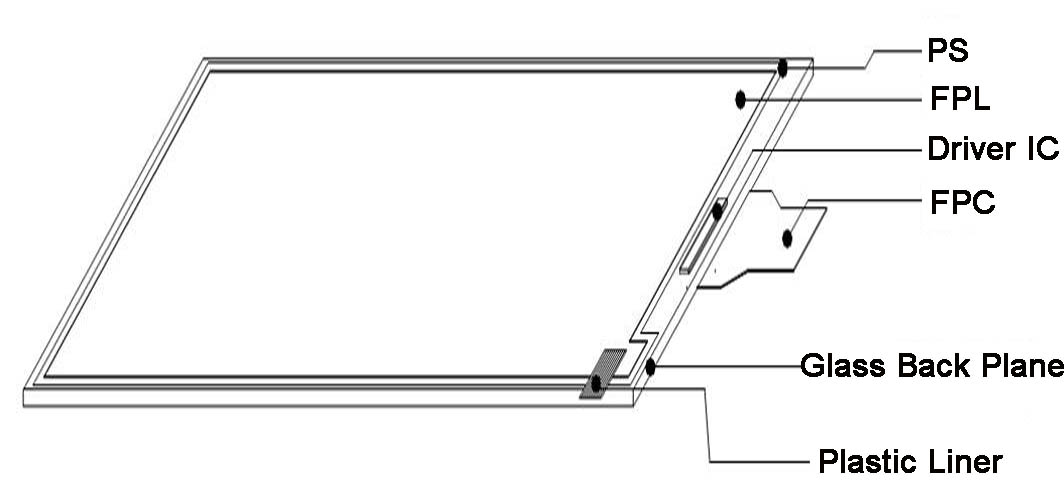

| TFT Glass Cutting | FPL Laser Cutting | Auto FPL Attaching | Auto FPL Attaching |

|

|

|

||

| Auto PS Attaching | Auto EC Coating | Production Line Overview |

|

FPL: Front Plane Laminate. COG: Chip on Glass. FOG: FPC on Glass. PS: Protective Sheet. EC: Edge Coating. RTV Silicone: Room-temperature-vulcanizing silicone. |